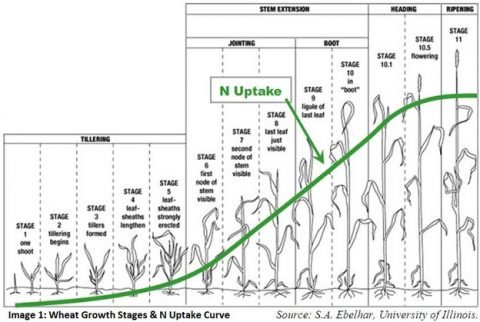

Cereals are very responsive to nitrogen. However, over-application of nitrogen causes lodging, which results in reduced yield, quality, and harvestability. The optimum rate of nitrogen for a particular field will depend on the type of wheat grown, past applications of manure or fertilizer, soil type, and crop rotation. Use general recommendations as a starting point, but combine them with observation of crop growth and lodging tendency. The idea is to ensure nitrogen is available early and consistently though the major uptake period (node development though booting).

TIMING

Could occur earlier, while providing N when the crop’s demand goes up. Large single applications increase potential for lodging in your crop. Time single applications of nitrogen for late April. This avoids significant N loss from wet soil conditions that

Split applications are preferred. The main benefits are reduced concerns over N loss, greater weed control due to increased crop vigor, more uniform heading, and less lodging. Yield benefits are secondary. Apply 50-80 lbs/ac N as early as possible (on frost any time after March 15-20), with the balance at 1st – 2nd node. Nodes can be easily seen or felt on the stem above ground level.

ABOVE: Wheat growth stages and nitrogen uptake curve.

Image Source: S.A. Ebelhar, University of Illinois.

RATES

Without fungicides, apply 90 lbs/ac N. It is not recommended to grow wheat without applying fungicides, as you will not achieve the highest yield potential that could be available with fungicides.

With fungicides, use 120 to 150 lbs/ac N depending on past field history, organic inputs, soil organic matter and nitrate levels, and economics. Beware of lodging when going with high rates. Try strip trials of different rates in the field to experiment and learn how to keep rates high, while avoiding lodging.

APPLICATION

To maximize yield, nitrogen must be applied uniformly across the field. Uniform application is more critical than the form of nitrogen fertilizer applied.

Urea-Ammonium Nitrate Solution (UAN) (28-0-0 or 32-0-0) applied with streamer nozzles gives excellent, uniform nitrogen application and has shown small yield advantages (2.5 bu/acre). UAN applied through streamer nozzles causes little or no leaf burn.

Applying 28% nitrogen (UAN) as an overall broadcast treatment (using flood jet or tee-jet nozzles) to emerged cereal crops is NOT RECOMMENDED. The addition of 28% to an herbicide application, especially contact herbicides, will greatly increase leaf injury and yield loss.

If applying dry fertilizer, airflow technology can be utilized to improve spreading uniformity, although uniformity is not guaranteed.

Spinner spreaders often have the greatest inconsistency in spread pattern. If spinners are employed, consider double spreading the field (i.e., 6-m or 20-ft centres at half the rate, instead of 12-m or 40-ft centres) to overcome this. Newer technology in spinner spreaders, especially with custom application, can improve the spread pattern and cut down on overlaps or streaking within the field. Be sure to ask your Sylvite Sales Rep or Ag Consultant to decide on the best option to fit your operation.

ABOVE: Streamer nozzles applying 28% UAN.

Image Source: C&M Seeds.

SULFUR

Sulfur should be added to every field along with your nitrogen application. With the decline of use of coal power plants over the last couple decades, much less sulfur is being emitted to the atmosphere and deposited over agricultural land. This has led to a decline in sulfur levels in the soil and essentially every field needs to have some sulfur added to avoid being deficiencies. The best general recommendation is to add 10 lbs/ac of sulfur to your nitrogen applications for winter wheat.

NITROGEN STABILIZERS

These products reduce the loss of nitrogen through natural processes such as ammonia volatilization, denitrification, and leaching. They are highly recommended to protect your nitrogen after application from difficult weather conditions. These products would be very beneficial in wet springs, on sandy and poorly drained soils, where leaching is prevalent, and when urea/28% UAN is surface applied.

CONTROLLED RELEASE NITROGEN

These products do not prevent nitrogen loss directly. Instead they control the release of nitrogen so that all is not available immediately. This is commonly done through sulfur coating on urea or more recently with superior polymer technology like in the product Environmental Smart Nitrogen (ESN).

Your Sylvite Sales Representative or Ag Consultant are eager to discuss the various product options to protect against volatilization, denitrification and leaching, or all three sources of N loss for your fields.